Natural

plain yoghurt contains only milk and lactic ferments

1 litre of milk

= 8 pots of yoghurt

Yoghurt and fermented milk: simple production with real know-how

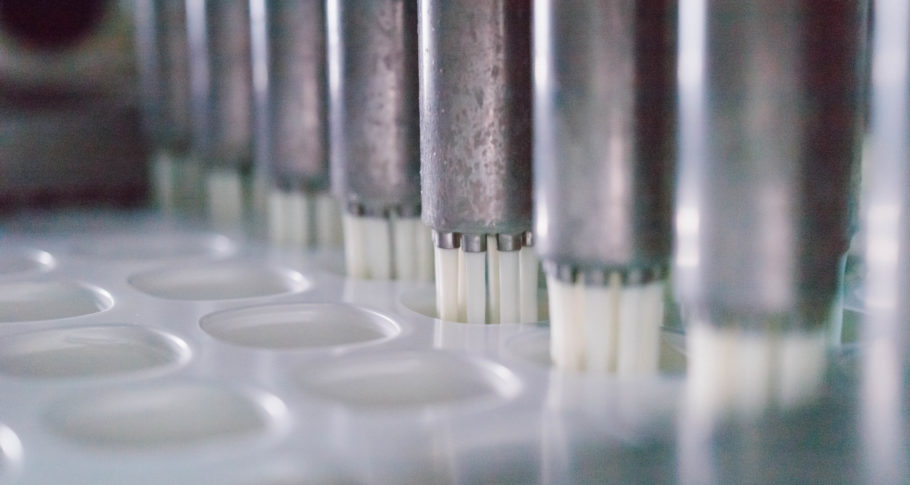

oghurt is made using a precise manufacturing process.

The milk, passing through the skimmer, is standardised in fat content. It can be concentrated by adding milk powder to give the finished products a firm and creamy texture.

Pasteurisation at 95°C is designed to eliminate undesirable microorganisms. Then the milk is cooled to a temperature of about 42°C and lactic ferments are added.

Lactic ferments transform lactose into lactic acid. This is lactic fermentation. The milk gels to form yoghurt. This takes 3 to 5 hours, in pots in an oven or directly in a tank, before being packaged and transferred to a cooling tunnel to stop the acidification.

In both cases and after fermentation, the pots are packed and kept at 6°C until they are eaten. Yoghurts can be kept for about 30 days.

Milk enzymes in yoghurt and fermented milks

Yogurt is not a 20th century invention. For several thousand years, humans have known how to “thicken” milk. Thanks to their acidifying action of the bacteria present, yoghurt is obtained and the milk is thus preserved for several days.

To qualify as yoghurt, two of the bacteria used are Lactobacillus bulgaricus which brings acidity to the yoghurt and Streptococcus thermophilus which develops the aromas.

Fermented milks other than yoghurts are manufactured on the same principle but the ferments used are not necessarily those of yoghurt. There are Lactococcus lactis, Lactobacillus acidophilus, Bifidobacterium and others. These bacteria remain alive when the yogurt is consumed.

They facilitate digestive transit. Yoghurt and fermented milks are considered to have beneficial digestive virtues in cases of intestinal disorders (lactose intolerance) and in the prevention of certain diarrhoea.

The production of dairy desserts

Milk desserts are made with a minimum of 50% milk. However, in most of them, the percentage of milk is as much as 75%. Unlike yoghurts and fermented milk, they do not contain lactic ferments and do not have the acidic character of yoghurts and fermented milks.

Milk is added in various quantities: sugar or equivalent, fresh cream, eggs and gelling or thickening agents, as well as chocolate, caramel, vanilla and other flavours.

Each dessert has its own production process

There are many types of dairy desserts and therefore many ways to prepare them. If milk remains the essential ingredient, the mixture obtained with milk and other ingredients may be subjected to different treatments:

- Egg-based creams, caramel creams, floating islands or crème brûlée are baked in the oven or in a bain-marie.

- Fluffy desserts where the mousse is beaten to obtain their light and airy texture.

- Renneted milk is curdled/jellied milk produced by rennet. It gives desserts that are not acidic, unlike yoghurt, and can contain a variety of flavours.

- Rice pudding, clafouti or semolina cakes use ingredients and manufacturing processes specific to their traditional recipe.

Different types of yoghurt

- “Firm” yoghurt: the ferments are directly added to the pots which pass through an oven at 42°-44°C for 3 to 5 hours.

- “Stirred” yoghurt: the ferments are added in tanks. The gel obtained after fermentation for 3 to 5 hours is stirred before being packaged and stored in a cold room.

- Drinkable” yoghurt: This is a liquid stirred yoghurt. It is stirred in the fermentation tanks and packaged in bottles.

- Yoghurts with 0% fat, semi-skimmed milk, or whole milk: skimmed milk that does not contain fat is used to make 0%-fat yoghurt, semi-skimmed milk to make semi-skimmed milk yoghurt and full-fat milk to make full-fat milk yoghurt.

- Fruit or flavoured yoghurts: Fruit yoghurts are natural stirred yoghurts to which a fruit preparation, similar to a jam, has been added after the fermentation, stirring and cooling stages. Flavoured yoghurts are natural yoghurts to which flavours have been added.

- Goat’s or sheep’s milk yoghurt: The manufacturing process is the same for all types of yoghurt. Only the origin of the milk changes.

Why additives?

Additives are used only when they fulfil a specific technological function and in strictly necessary doses, as defined by regulation. For example, a sweetener can be used in flavoured fermented milk with a reduced sugar content to compensate for the loss of sweet taste.

Thickeners can be used in low-fat products to maintain the structure and texture of the product.

Companies are increasingly limiting the use of additives that are only used when they are essential for technical reasons.